SHEEP

HUSBANDRY

Sheep

farming as a rural activity is subject to the vagaries of the

Australian climate. For example:

- Whether or not

feed will be available for lambs in autumn, winter or spring

- When it is warm

enough to shear for safety

- When it is too

hot to mate rams

- When the grass

seeds are most troublesome

- When blowflies

are at their worst

- When rains can

cause the hatching of worm eggs.

TIME

OF SHEARING

The time of

shearing is the most important date to be fixed in the sheep year. It

begins as early as May or June in the warmer parts of Queensland and

later as one moves south. In the colder parts of NSW and Victoria

sheep are usually shorn in October or November. Skin parasite control

follows

shearing because parasites are more easily killed when

the wool is short. Other procedures have to be timed according to

the local climate.

MATING

Ewes need good

feed just before lambing and for some time after. The season when

the feed is available usually decides the time of mating. Lambing

occurs 150 days or 5 months after mating. Sheep breed best in the

autumn months but can only be mated then if there promises to be

enough spring feed for the lambs.

Spring lambing is

popular in the colder parts of NSW and Victoria and in some western

areas the sheep being mated in April-May. All mating should be

completed within a short a time as possible (not more than 6 weeks)

with 2 or 3% of rams being used. “Flushing” is the practice of

putting all breeders onto good feed 2 or 3 weeks before joining them.

This will increase

the lambing rate.LAMBING: Six weeks before ewes are due to lamb they

should be crutched, wigged and put into a lambing paddock where they

can be kept undisturbed and with good feed. At 9 weeks and at 3 weeks

before lambing they may be vaccinated to prevent entero-toxaemia

or pulpy kidney. As soon as lambing begins the ewes should be

constantly supervised and help given to any ewes requiring it.

Lambing losses occur from cold, feral pigs, wet, foxes and pregnancy

toxaemia if not properly managed.

MARKING

Marking occurs 3-6

weeks after lambing. All lambs should be marked as follows:

- EAR MARKING

The cutting of a

registered mark in the right ear of ewe lambs and the left ear of ram

lambs.

- AN AGE MARK

A mark in the

other ear so that the age of the sheep is easily seen during drafting

and culling.

- RAM LAMBS

Not required for

breeding are castrated becoming dry sheep or wethers.

- DOCKING

Of the tail at

the 2nd or 3rd joint so that the crutch remains

drier and therefore, less subject to fly strike.

- INOCULATED

With a 5 in

1 vaccine. Losses can occur though the use of non sterile instruments.

TOOLS

FOR TAGGING

WEANING

Lambs

are commonly weaned at 4-5 months of age. Lambs are weaned by

separating from their mothers and put into sheltered paddocks with a

good water supply, and with young green feed such as improved

pasture. This is a high danger period for worm infestation. The main

symptom is a lack of weight gain for example, merino lambs should

gain about 700 grams per week. If the gain is less then they are

probably infested with worms.

CLASSING

On a breeding

property each year more ewes are added to the flock and therefore,

the grazier must class to decide which ones to keep for breeding.

Unless the worst ewes are culled the average fleece weight will not

increase and may fall. Since wool is the main income earner for most

sheep graziers it is not usual to class and cull until they are

carrying at least 9 months of wool and with some studs not until they

are in full wool. There are two ways to class:

- SUBJECTIVE

CLASSING

The sheep are

yarded up and judged as they come through the race culling all old or

undersized sheep or those with obvious body faults (such as undershot

jaw, devil’s grip, narrow shoulders, bad leg faults or ewes with bad

udders). Kempy hairs on the face, legs or thighs, light mushy wool or

back wool which opens up too much thus admitting moisture. Sheep are

selected on the basis of good health and carrying the largest amount of

uniform quality wool . This type of classing is called “subjective

classing” because it is based on the appearance of the sheep.

- OBJECTIVE

CLASSING

Objective

classing is carried out by weighing the wool and is carried out at

shearing. Fleece weighing can result in twice the improvement gained

from subjective classing. However, for best results, classing should be

both subjective and objective.

OBJECTIVE MEASUREMENT

KIT OF WOOL

DRENCHING

Drenching

provides protection against worm parasites. It is usually carried

out by putting the mob in yards and then through a race. They are

packed tightly in the race so that they can be more easily dosed with

a drenching gun. They are then moved quietly to pasture.

ADVERTISEMENT

FOR A “BACKLINE SYSTEM” FOR LICE CONTROL

CRUTCHING

Crutching

is an important sheep farming activity and is the removal of wool

from the back of the legs, the breech and over the tail. This

reduces blowfly strike of the breech were the wool is wet from urine.

It is carried out with hand shears in the yard or through the

shearing shed. Crutching is usually carried out before mating or

lambing typically, during March or July.

DIPPING

Dipping

controls other external parasites such as itchy mite and blowflies.

Traditional drenching is being overtaken by technology for example,

applications directly on the back of sheep are becoming more popular.

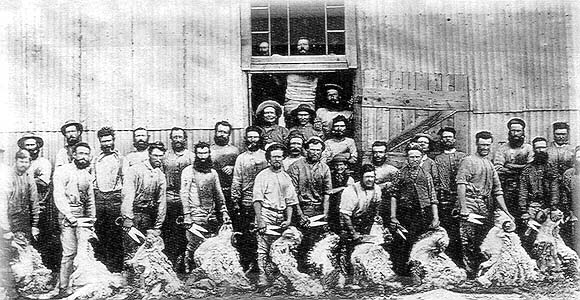

SHEARING

The owner arranges

with a shearing contractor to arrive with his team of shearers on a

certain day. A great deal of preparation is required beforehand. For

example, the shearing shed must be put in order, shearers huts

cleaned, and firewood gathered. The sheep have to be mustered and

sorted into groups so that they will go through the shed in uniform

lines of ewes, weaners, wethers, lambs and rams. If rain threatens

the sheep must be put under a roof (often in a yard under the

shearing shed) as shearers will not shear wet sheep.

The size of the

team depends on the size of the shed for example, in a 4 stand shed

the following people would be needed:

- The contractor

who will do some shearing

- 4 shearers

- The cook and

perhaps a cook’s offsider

- The classer who

is employed separately

- The presser

- 1 or 2 wool

rollers who pick up fleeces from the board and roll them after classing

has been done.

- A “rouseabout”

or general handyman

- The expert who

looks after the engine and keeps the shearing cutters and combs

sharpened.

An

average shearer can shear at the rate of one sheep every 2 or 3

minutes but catching sheep and changing cutters and so on wastes

time. A good shearer can shear about 120 sheep a day.

See

sheep – disease & management problems

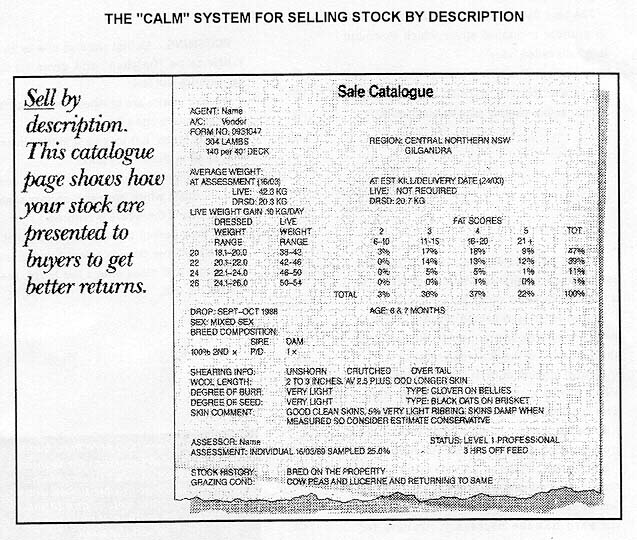

OBJECTIVE

MARKETING – EXAMPLE: CALM

An

important marketing system is CALM. Under this system the sheep are

described and graded by a qualified assessor. The stock are then

sold through the CALM system to a buyer who does not see the sheep

but relies instead on the assessor’s judgment.

9